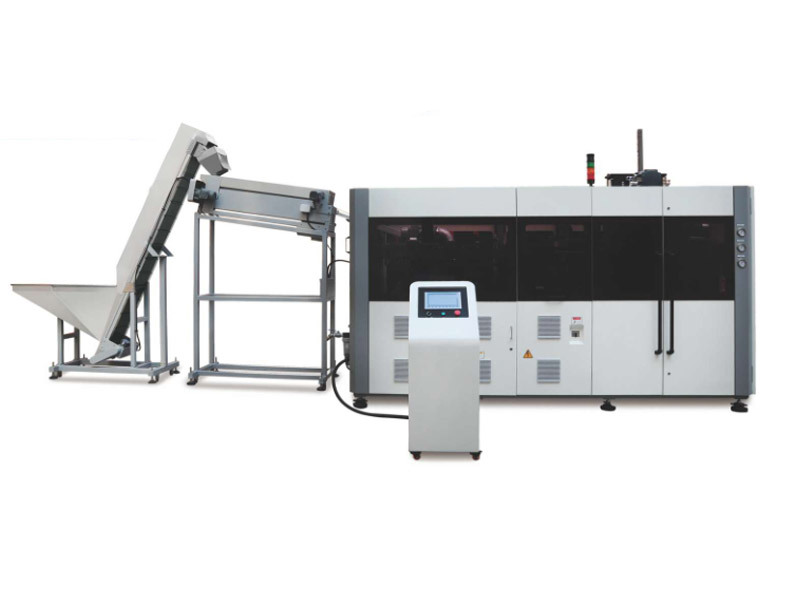

Linear Full Servo Blow Moulding machine

Category:

Summary:

Linear Full Servo Automatic Blow Moulding Machine is suitable for producing different shape and type PET bottles.New design of 7 cavity,small space,high speed,low power.It is widely used to produce the carbonated bottle, mineral water,hot fill bottle,beverage bottle, medicine bottle etc.

- 技术参数

- 详细描述

-

- Commodity name: Linear Full Servo Blow Moulding machine

Product Introduction

SJ-CP7 Linear Full Servo Automatic Blow Moulding Machine is suitable for producing different shape and type PET bottles.New design of 7 cavity,small space,high speed,low power.It is widely used to produce the carbonated bottle, mineral water,hot fill bottle,beverage bottle, medicine bottle etc.

Feature

(1)Feeding system

Continuous and high speed preform feeding system.Multiple protection device for precise preform feeding.

(2)Transfer and heating system

Horizontal rotation transfer system to eliminate preform flipping.Compact preform-chain pitch design for efficient heating and reduce energy consumption.Cooling ramps throughout for maximum preform neck protection.Optimized exhausting and preform surface cooling system.Infrared heat sensor for preform temperature monitoring.Easy access for heater maintenance and lamp changing.

(3)Transfer and fetch system

Servo motor driven preform transfer system for quick transfer and precise preform locating.

(4)Blowing and clamping system

Servo motor driven system with synchronized base blow mold for fast response operation.Precision electromagnetic valves for fast responding time and high volume production.

(5)Control System

Touch-panel control system for simple operation 9 inch LCD touch screen with 64K colors.

(6)Other

All electric mechanism to ensure high-speed operation and precise locating.Design for quick mould change.Low energy consumption,low wear,low pollution.ITEM Unit SJ-CP5 SJ-CP6 SJ-CP7M SJ-CP8S SJ-CP7 SJ-CP8M SJ-CP9S PRODUCT Number of Cavities PC 5 6 7 8 7 8 9 Max.Capactity L 2.5 1.5 1 0.7 1.5 4 0.7 Max.Neck Diameter mm 30 30 30 30 30 30 30 Max.Body Diameter mm 110 90 80 70 90 80 70 Max. Bottle Height mm 350 350 300 300 350 300 300 Theoretical Output B.P.H 9000 11000 13000 15000 13000 15000 16000 MOULD Spindle Chain Pitch m 38 38 38 38 38 38 38 Cavity Pitch m 125 110 90 80 110 90 80 ELECTRICAL Max.heating Power KW 50 40 40 36 80 80 72 Servo Motor Power KW 14.5 14.5 14.5 14.5 14.5 14.5 14.5 Other Motor Power KW 4.2 4.2 4.2 4.2 5 5 5 Total Power KW 69 59 59 55 110 100 92 Voltage/Frequency V/HZ 380V±10% 50HZ/220V±10% MACHINE Size(L*W*H) M 5.2*1.5*2.3 5.2*1.5*2.3 5.2*1.5*2.3 5.2*1.5*2.3 5.8*1.5*2.6 5.8*1.5*2.6 5.8*1.5*2.6 Weight KG 5500 5500 5500 5500 6000 6000 6000 REMARK

1、The production capacity is determined by preform type and intended bottle type.

2、High-pressure air consumption is determined by bottle size and production capacity.Specificatons are subjected to change without notice.

Keywords:- Stretch Blow Moulding Machines For sale

- Stretch Blow Moulding Machines company

- Stretch Blow Moulding Machines products

Product Introduction

SJ-CP7 Linear Full Servo Automatic Blow Moulding Machine is suitable for producing different shape and type PET bottles.New design of 7 cavity,small space,high speed,low power.It is widely used to produce the carbonated bottle, mineral water,hot fill bottle,beverage bottle, medicine bottle etc.

Feature

(1)Feeding system

Continuous and high speed preform feeding system.Multiple protection device for precise preform feeding.

(2)Transfer and heating system

Horizontal rotation transfer system to eliminate preform flipping.Compact preform-chain pitch design for efficient heating and reduce energy consumption.Cooling ramps throughout for maximum preform neck protection.Optimized exhausting and preform surface cooling system.Infrared heat sensor for preform temperature monitoring.Easy access for heater maintenance and lamp changing.

(3)Transfer and fetch system

Servo motor driven preform transfer system for quick transfer and precise preform locating.

(4)Blowing and clamping system

Servo motor driven system with synchronized base blow mold for fast response operation.Precision electromagnetic valves for fast responding time and high volume production.

(5)Control System

Touch-panel control system for simple operation 9 inch LCD touch screen with 64K colors.

(6)Other

All electric mechanism to ensure high-speed operation and precise locating.Design for quick mould change.Low energy consumption,low wear,low pollution.

| ITEM | Unit | SJ-CP5 | SJ-CP6 | SJ-CP7M | SJ-CP8S | SJ-CP7 | SJ-CP8M | SJ-CP9S |

| PRODUCT | ||||||||

| Number of Cavities | PC | 5 | 6 | 7 | 8 | 7 | 8 | 9 |

| Max.Capactity | L | 2.5 | 1.5 | 1 | 0.7 | 1.5 | 4 | 0.7 |

| Max.Neck Diameter | mm | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Max.Body Diameter | mm | 110 | 90 | 80 | 70 | 90 | 80 | 70 |

| Max. Bottle Height | mm | 350 | 350 | 300 | 300 | 350 | 300 | 300 |

| Theoretical Output | B.P.H | 9000 | 11000 | 13000 | 15000 | 13000 | 15000 | 16000 |

| MOULD | ||||||||

| Spindle Chain Pitch | m | 38 | 38 | 38 | 38 | 38 | 38 | 38 |

| Cavity Pitch | m | 125 | 110 | 90 | 80 | 110 | 90 | 80 |

| ELECTRICAL | ||||||||

| Max.heating Power | KW | 50 | 40 | 40 | 36 | 80 | 80 | 72 |

| Servo Motor Power | KW | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 |

| Other Motor Power | KW | 4.2 | 4.2 | 4.2 | 4.2 | 5 | 5 | 5 |

| Total Power | KW | 69 | 59 | 59 | 55 | 110 | 100 | 92 |

| Voltage/Frequency | V/HZ | 380V±10% 50HZ/220V±10% | ||||||

| MACHINE | ||||||||

| Size(L*W*H) | M | 5.2*1.5*2.3 | 5.2*1.5*2.3 | 5.2*1.5*2.3 | 5.2*1.5*2.3 | 5.8*1.5*2.6 | 5.8*1.5*2.6 | 5.8*1.5*2.6 |

| Weight | KG | 5500 | 5500 | 5500 | 5500 | 6000 | 6000 | 6000 |

REMARK

1、The production capacity is determined by preform type and intended bottle type.

2、High-pressure air consumption is determined by bottle size and production capacity.

Specificatons are subjected to change without notice.

Keywords:

Stretch Blow Moulding Machines For sale

Stretch Blow Moulding Machines company

Stretch Blow Moulding Machines products

RELEVANT

Wide-Mouth Automatic Bottle Blowing Machine